OSHA’s New Regulations

COVID is an ever-evolving disease with a multitude of governing bodies adjusting their regulations to keep everyone safe. Building owners have continued to adapt. This month’s newsletter is focused on COVID’s impact on office building regulations and what tools the experts are using to cope with the evolving demands.

According to pathogen and environmental health expert, Dr. Richard Wade, “What you use to decontaminate surfaces is a function of EPA and their list of approved chemicals. When you let people back in, the kind of surveillance and decontamination, and guidelines on physical separation is established by the Center for Disease Control and Prevention (CDC). And the enforcement of reporting and complaints about outbreaks or conditions in the workplace is the responsibility of the Occupational Safety and Health Administration (OSHA).”

OSHA and the Guide to COVID

Washing hands and the proper use of face masks have been drilled into people’s heads as the simplest, most effective way to prevent the spread of COVID-19. But in the workplace, definitive safety procedures must be followed around the clock to ensure continued safety. On top of all other applicable laws, regulations, and standards, businesses must comply with COVID-RELATED OSHA GUIDELINES AND LAWS applicable to their industry. The information provided was translated in tandem with the suggested practices and procedures put forth by the CDC to be trade specific.

Building owners have taken on the additional tasks of building maintenance to adhere to OSHA’s safety regulations and guidance. One major factor: HVAC. Ventilation is a highly critical component for the prevention and attenuation of airborne contaminants like COVID-19. The typical commercial lease and property management agreements do not address viral epidemics. The duties and obligations of a landlord or property manager regarding limiting employee, tenant, and guest risk of exposure to the virus depend on what services the landlord or property manager provides at the property. The suggestion is to follow the guidelines set forth by OSHA and the CDC.

The Cost & Financial Implications of Safe Practice

Staying open and conducting business during the pandemic comes at a price, especially for building owners. To follow new regulations, buildings must not only exercise extra sanitation practices but reconfigure or renovate their spaces for better filtration and social distancing. Big companies reported spending anywhere from hundreds of thousands to almost a billion dollars in COVID-19 related costs. They expect the costs to rise into 2021.

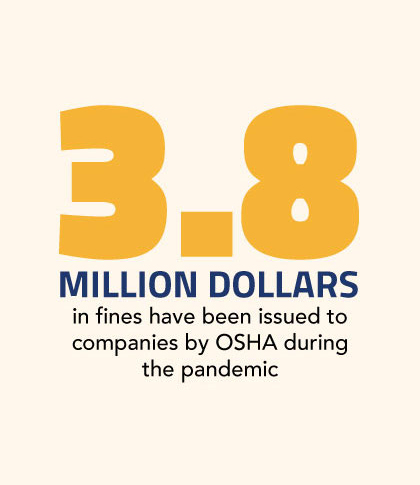

At the end of December, OSHA reported the issuance of over $3.8 million in virus-related citation penalties to 294 businesses since the beginning of the pandemic. The various violations run the gamut from failure to implement written protection programs to failure to report illnesses and fatalities, which indicates negligence of record-keeping programs. Fine amounts are on a state-by-state basis and depend on the number of violations incurred. Below are a few reported examples of the COVID-related violations and fines businesses incurred in 2020:

Keeping Buildings Safe

New Jobs, New Departments, New Companies

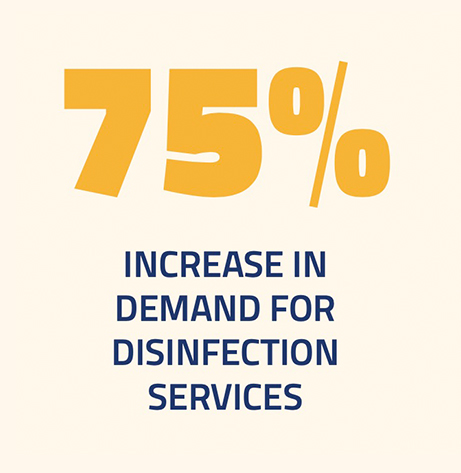

As our knowledge of the coronavirus evolves, so do our requirements in keeping buildings safe. The constant evolution impacts building codes and work requirements almost daily, creating new roles and departments focused solely on keeping up with the changes. Building owners are adding to their cleaning staff—a work sector that has experienced a 75% increase in demand. They’re also creating entire departments focused on cleanliness, circulation, and ventilation.

While healthcare is the most prominent sector feeling the constant change in building requirements, corporations and commercial properties are also creating jobs and departments to adhere to the new rules and regulations. Last February, Nate Seward, PE, CIH saw an opportunity to develop an educational “Pathogen Standard of Care” designed to reduce the risk of infection from SARS-CoV-2 within the workplace. Founded by environmental, industrial hygiene and restoration experts, Pathogen Response & Resource Alliance (PR2) came into fruition at the pandemic’s onset in order to help companies keep their employees safe and employers in compliance with safety regulations.

“Before 9/11, we didn’t take our shoes off at the airport, and we had full water bottles. After 9/11, there was a new normal for airport security. Experts agree that there will be more pandemics in the future and there is no doubt that building hygiene and cleaning will also have a ‘new normal.’ It starts with education and proper training/certification of employees and professionals to maintain buildings at the highest hygiene level possible.” – Nate Seward

The firm has created a desperately needed Standard of Care for Pathogen building disinfection and provides training and certifications for office workers, non-office workers, and professionals providing pathogen disinfection within businesses and homes across the US. According to Seward, PR2’s Chief Industrial Hygienist, “the standard practices and protocols for keeping our workplace and homes clean with an increased level of hygiene against pathogens will never be the same.”

Seward, along with other toxicologists and pathogen experts, predicts there may be at some point a new way of rating buildings as it relates to overall hygiene in the future. In the restaurant industry, many states require health departments to give the establishment an alphabetical rating, one that must be posted in a clear, visible spot to patrons. To ensure employee and consumer confidence in the workplace, a similar hygiene program for office buildings may be on its way.

Disinfecting Buildings: Innovative Solutions

Vapor Barriers & Negative Pressure Rooms

At the beginning of the pandemic, little was known about the spread of COVID-19. Hospitals were in survival mode and prevented spread through detailed surface cleaning practices and PPE. Once it was discovered to be an airborne virus, hospitals became innovative with their HVAC systems and started creating temporary negative pressure rooms, which slowly became a staple in COVID units.

Negative pressure rooms maintain lower air pressure inside the room versus outside the room. Non-contaminated “outside” air flows into the room while the contaminated air inside the room is forced out through the negative air machine. These negative air machines are equipped with HEPA filters to clean the exhaust of any airborne contaminants before being pushed outside and away from the hospital. To further mitigate leakage and cross-contamination, namely when entering and exiting the room, many of these systems contain a vapor barrier enforced “anteroom,” an airlock space for healthcare providers to change into their PPE.

Dr. Wade & Disease Control

As businesses trudge through the pandemic, struggling to return to pre-COVID “normalcy,” questions arise. It is during these times, more than ever, professionals bring in the experts. For many businesses, that man is Dr. Richard L. Wade. Having studied at the University of Michigan and Harvard, procuring degrees in biological chemistry, environmental engineering and public health, Dr. Wade has long been a reliable expert. In the early days of ATI, he guided teams on proper lead and asbestos removals from old buildings.

Since then, he has served as the expert in handling various large catastrophes, such as hospital decontamination after Hurricane Katrina. He also provides company-wide updates on new information through routine workplace safety seminars, giving employees a forum to ask questions.

“When companies experience a high level of stress, from a risk management standpoint, they need engineering and scientific oversight to guide them through these time sensitive, ‘gotta move, gotta do it’ scenarios,” says Dr. Wade. “Otherwise, they make rash decisions without all the information.”

He has also helped develop specialized, touchless sterilization technologies, informing and training crews on why and how to use them. One technology widely adopted by a myriad of industries (hospitals, restaurants, hotels, schools, sports venues, prisons, et al.), is UV light. In collaboration with R-Zero, Dr. Wade has helped design and build a groundbreaking, touchless sterilization method in the form of a free-standing, easy to use UV lighting that can continually treat air and decontaminate a 1,000 square foot space in under ten minutes. He also advocates the use of hydrogen peroxide-based aerosolization for surface disinfection.

The COVID world has become complicated. With so many governing bodies dishing out copious amounts of information, it’s hard to identify what is reliable. After working with the World Health Organization (WHO), California OSHA, and the environmental health department for Seattle and Minnesota, Dr. Wade is keen on identifying strong information and research.